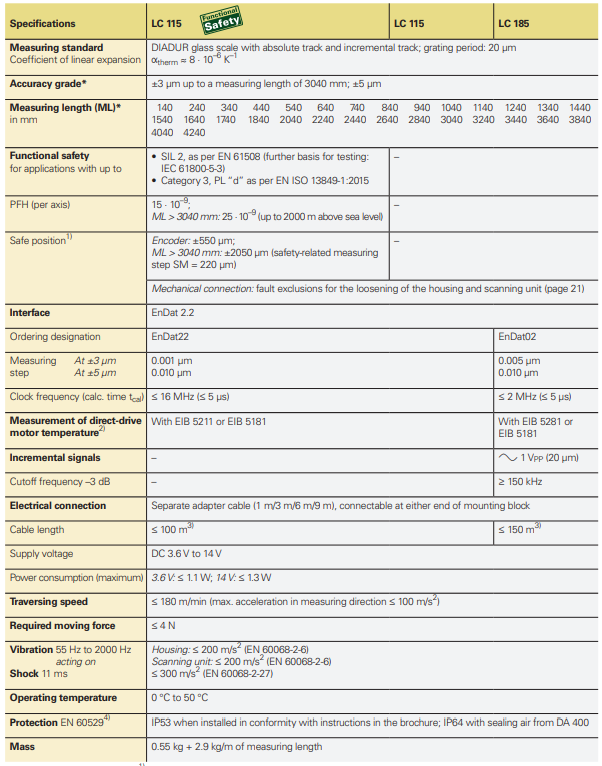

LC100 and LC200 series Absolute linear encoders provide absolute position value directly, no need return to zero before measurement. Some models also offer incremental output signals additionally. The fitting size of the LC100 is same as that of the LS100 series incremental linear encoders, and the mechanical structure is also the same. LC100 and LS100 series linear encoders are particularly suitable for NC machine tool applications due to their high accuracy and definable temperature characteristics.

Heidenhain's absolute linear encoders provides accurate position value directly, there is no need to move the axes to find the reference position. The absolute position information is read from the scale graduation, which is designed as a serial absolute code structure. A separate incremental track is interpolated for the position value and is simultaneously used to generate an optional incremental signal. Simply put, Heidenhain absolute encoders has the following advantages compared with the incremental encoders:

1. The distance between each two lines is unique, so the current position value can be displayed when the machine is power off and then switched on to facilitate subsequent processing;

2. The data transmission is more stable and strong anti-interference ability (many incremental signals require large electronic subdivision error);

3. Low cost, shorter transmission time, support advanced system machine tool technology; 4. Support safety technology online diagnosis (you can view the grating ruler signal quality in the Heidenhain system); Support limit switch, temperature, acceleration recording data and other additional functions.

Common models are:

LC481/LC483/LC485/LC185/LC183/LC193F/LC195F/LC193F/LC195F/LC493F/LC495F/LC493M/LC493M/LC195P etc.