| KSK CZ Ball Screw |

| Date:2022-04-06 15:50:51 | Visits: |

KSK has been manufacturing ball screws since 1967 and has sold its products all over the world. In order to provide customers with high-quality products and efficient services, KSK has been continuously improving technology, research and development. Because of this, we are able to achieve excellent results in the world's leading technological innovation competitions. The certification of the EN ISO 9001:2008 Product Quality management system attests to KSK's high quality products. At the same time, KSK also provides maximum support for regional industrial machinery technology projects and becomes a member of the following institutions:

Features of KSK products favored by customers:

Products Application: Ball screw (hereinafter referred to as BS) is a high-efficiency structural element that converts rotary motion into linear motion (BS does not have a self-locking function). It is characterized by high rigidity, high accuracy and durability. Ball screws are widely used in various industrial equipment because of their high efficiency and low rolling resistance. The most commonly used industrial fields are:

Ball Screw: In principle, the ball screw consists of the following components: • The screw • nut (or double nut) includes circulating, prepressing, sealing and lubricating elements • the ball

Standard manufacturing technology of ball screw thread: The accuracy and quality of ball screws are largely dependent on manufacturing technology. Generally speaking, the following techniques are mainly used: • Grinding thread (accuracy level up to IT1) • Cold rolling thread (accuracy level up to T5)

Ball screw appearance: In order to achieve maximum transmission efficiency, it is necessary to improve the appearance of the ball screw. It is composed of two radii opposing each other (the so-called "Gothic arch" pictured below). This shape provides the ideal load ratio (grade) for the ball screw.

Prepressing method of ball screw:

Production of raw materials for ball screws and raw material heat treatment: According to the Czech national standard, KSK uses steel 42CrMo4, CF53 and 14 260 for the manufacture of screw, and steel 14 209 or 14 109 for the manufacture of nuts. The hardness of the nut and lead screw thread can reach 58-60 HRC. The minimum strength of the core part and unhardened part of the lead screw is Rm = 650 MPa. The quality of the finished product must pass long-term durability testing and reach specific wear limits by analyzing the functional parts of the product. Based on the information and knowledge obtained in the actual operating conditions, the life of the actual product can be guaranteed or the product can be optimized according to the known conditions.

Product load (class), rigidity and life of recirculation system: Another main parameter of the ball screw is the load capacity, and there are two main types of loads: a) static load (Co). Static load refers to the static load applied when the permanent deformation of 0.0001 times the ball diameter (Dw) occurs at the maximum contact stress point between the ball and the raceway surface. b) Dynamic load (Ca). Dynamic load is constant load. Under the condition that the basic rated life is L10 = 1×106 RPM, the ball screw can theoretically withstand a constant load. Basic rated life of ball screw. When a batch of the same ball nuts operate at a higher speed under the force of load F, 90% of the ball screw does not produce fatigue flaking, that is, the reliability rate is 90%, until the fatigue damage of the material or recycling function is found for the first time, which is the basic rated life.

Ball screw assembly accuracy: The ball screw requires precise installation. The parallel clearance between the lead screw and the guide shaft surface is controlled at 0, 02mm / 1000 mm. The verticality between the nut and the vertical axis should meet the tolerance of 0,01 within the range of 100 mm. Nuts can only be loaded axially. The design of long and narrow ball screws must ensure that the drive assembly can compensate for shaft displacement due to weight (support or rotary nut design modifications).

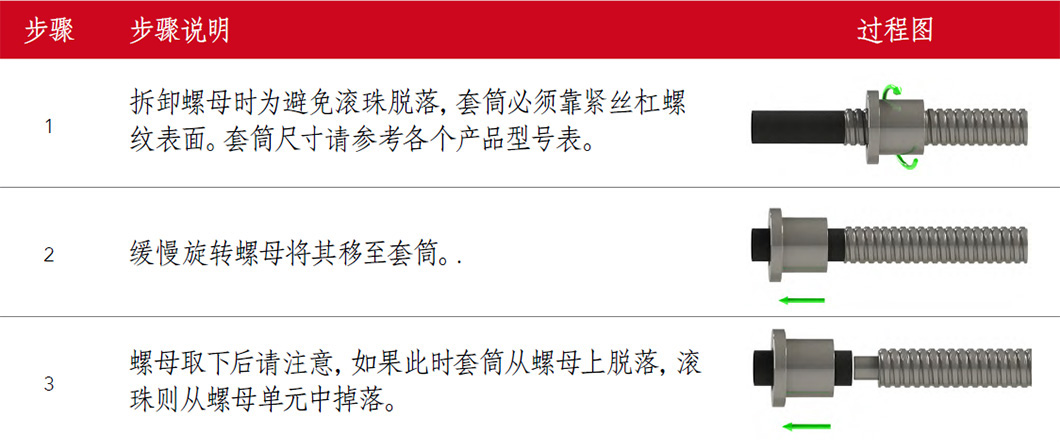

Nut assembly and disassembly: To remove the nut from the finished ball screw and reinstall it, follow these steps (the ball screw product warranty is void if the ball screw is damaged due to improper installation and disassembly) :  |

| Prev: Next:Germany Heidenhain |